Biomimetics

An innovative, totally biological process

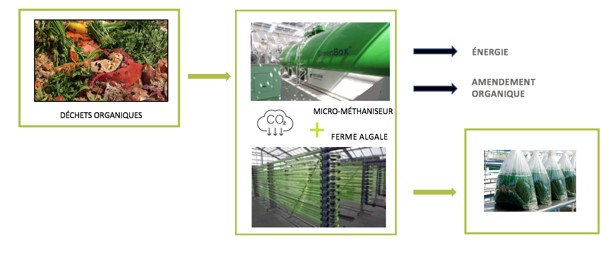

Our space-saving and non-polluting installations are deployed on surfaces of approximately 2000 m2.

They are sized to recover up to 5 tons per day of fermentable organic waste and are composed of 2 technical units:

A micro-methanizer to transform the waste and a 15 m3 photobioreactor to valorize it into an algal biostimulant product.

Methanization

A biological technology

Methanization consists in transforming organic waste into biogas (60% methane (CH4) and 40% carbon dioxide (CO2)) and solid and liquid digestates.

We valorize the CH4 in producing electricity. The solid digestate with a composition rich in fertilizing elements makes it an organic amendment of choice for agricultural crops because it improves microbial activity and soil respiration unlike conventional spreading of manure or slurry.

CO2 and liquid digestate are used to compose the culture medium for microalgae.

Microalgae

At the origins of life on Earth,

microalgae are 100% natural purification and transformation agents with exceptional environmental virtues.

They are photosynthetic organisms that grow using light as an energy source, CO2 as a source of carbon, and the nutrients they find in the liquid digestate to feed themselves.

Production

A closed, controlled and automated system

We cultivate the microalgae in a closed tubular photobioreactor (culture tank). A continuous circulation current avoids the formation of biofilm which allows an optimal illumination at all points of the culture basin.

We inject a growth medium composed of liquid digestate and carbon dioxide into the photobioreactor and we inoculate the strains.

Harvest

A vitamin solution

rich in trace elements,

and amino acids.

After harvesting, the microalgae are separated from the culture medium by centrifuging.

On one hand, we obtain a concentrated biomass that we valorize as a plant biostimulant for organic farming; and on the other hand, we obtain clean water that we use as cleaning or irrigation water.